Driving manufacturing to reality through Digital Manufacturing

Process engineering encompasses various aspects of product realization such as:

- “Make” or “Buy” decision making considering manufacturing capabilities, volume requirements, production schedules & costs

- Selection of suitable, cost effective and long lasting manufacturing processes

- Sequence of operations considering functional requirements of product

- Identify tooling requirements, gauges and other equipment needed to manufacture the product

- Design modifications that can help simplify manufacturing processes and reduction in manufacturing costs

- Re-alignment of manufacturing processes to accommodate new products in existing set ups

Satven has acquired expertise in field of process engineering and supported our customers. We can help in designing the product that fulfils the end customer requirements and manufactured economically with efficient manufacturing processes.

Some of the examples of our service offerings include-

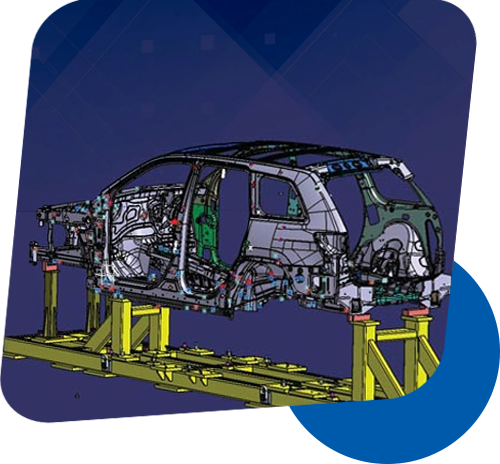

- Tool, hand space and clearance checks

- Assembly simulation

- Part load & ergonomic simulation

- Process study and optimization

Satven’s software competency include-

- CATIA V5/V6

- DELMIA

- TECNOMATIX Process Simulate

Digital Manufacturing - Technology for Virtually visualizing the Manufacturing/Factory scenarios in 3D environment before the actual factory installation

Satven allows manufacturers to virtually experience High-Level Manufacturing Processes, Detailed Design & Simulation for Human Ergonomics, Robotics process and NC Machines.

Benefits in offering:

- Before Start of Production Provide Manufacturability by Simulating Manufacturing Operations.

- Integration of Product Design and Manufacturing Processes (Concurrent engineering).

- Reduction in Product Development lead time to launch the New Product thereby reduction in development Costs.

- Validate Manufacturing Processes, Production Systems, and operational resources through Virtual Commissioning prior to physical implementation on the shopfloor and Reduce/Eliminate Prototypes & Physical Mockups.

- Faster Ramp-up for increased Production volumes / variants.

- High flexibility in managing manufacturing resources like time and effort so that the best new product can be manufactured and delivered.